Introduction

This tech-talk is about why simple isn’t always easy and what the Shack-Hartmann (SH) module in WaveMe must do to make life easy for you.

In an earlier tech-talk, we elaborated on the calibration of SH sensors in general and, in the end, how and why we choose to do things differently in the SH module for WaveMe.

First, let’s revisit the primary purpose of this module: offering a user-friendly application that you would choose before anything else when setting up an optical system. As an example, for collimation, my ambition is that you pick the sensor before you pick your business card. Yes, I know, the business card is tempting. It’s so simple, but so is WaveMe’s SH module. You only have to put in in front of your beam and you’ll have access to precision and quantifiable results that cannot be achieved with a business card. Sure, the business card costs less, but your time is valuable. If you too value your time, I believe you will find WaveMe to be the clear choice.

The problem to solve – Where’s the source?

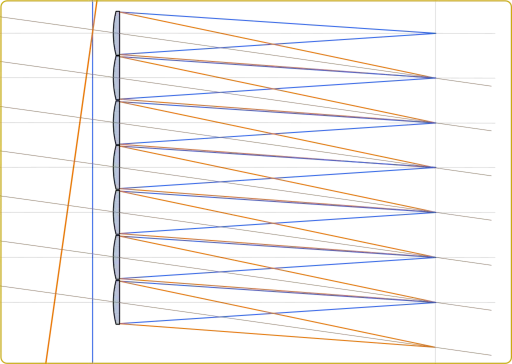

Here’s a glimpse of what the SH module needs to solve to make things simple. I’ve mentioned before that the SH module generates its calibration dynamically in order to free the user from the need of aligning the sensor. At face value, that is completely true. But there is a problem that the software needs to address, where does the light really come from? To illuminate this further, have a look at the figure below.

The blue lines are showing a plane wave illuminating the lens array at right angles, eventually being focused on the detector. The orange lines are illuminating the lens array at a different angle but are perfectly focused on the same positions as the blue lines. How do we see the difference between orange and blue? The CMOS detector itself is certainly not sensitive to direction. We cannot move the array and under no circumstances am I not going to ask you to align the SH sensor itself. That would defeat the entire purpose, not to mention that next time, you’d go for the business card. We certainly don’t want that.

The cheap trick, of course, would be to look for the border of the lens array. Fundamentally, we face this problem due to periodicity which ends at the border. But what happens if you, as would often be the case, project your exit pupil on the lens array. Then there is no border to be found. The spot patterns for the different angles of incidence would look identical. How do we tell them apart?

As always – It’s in the details

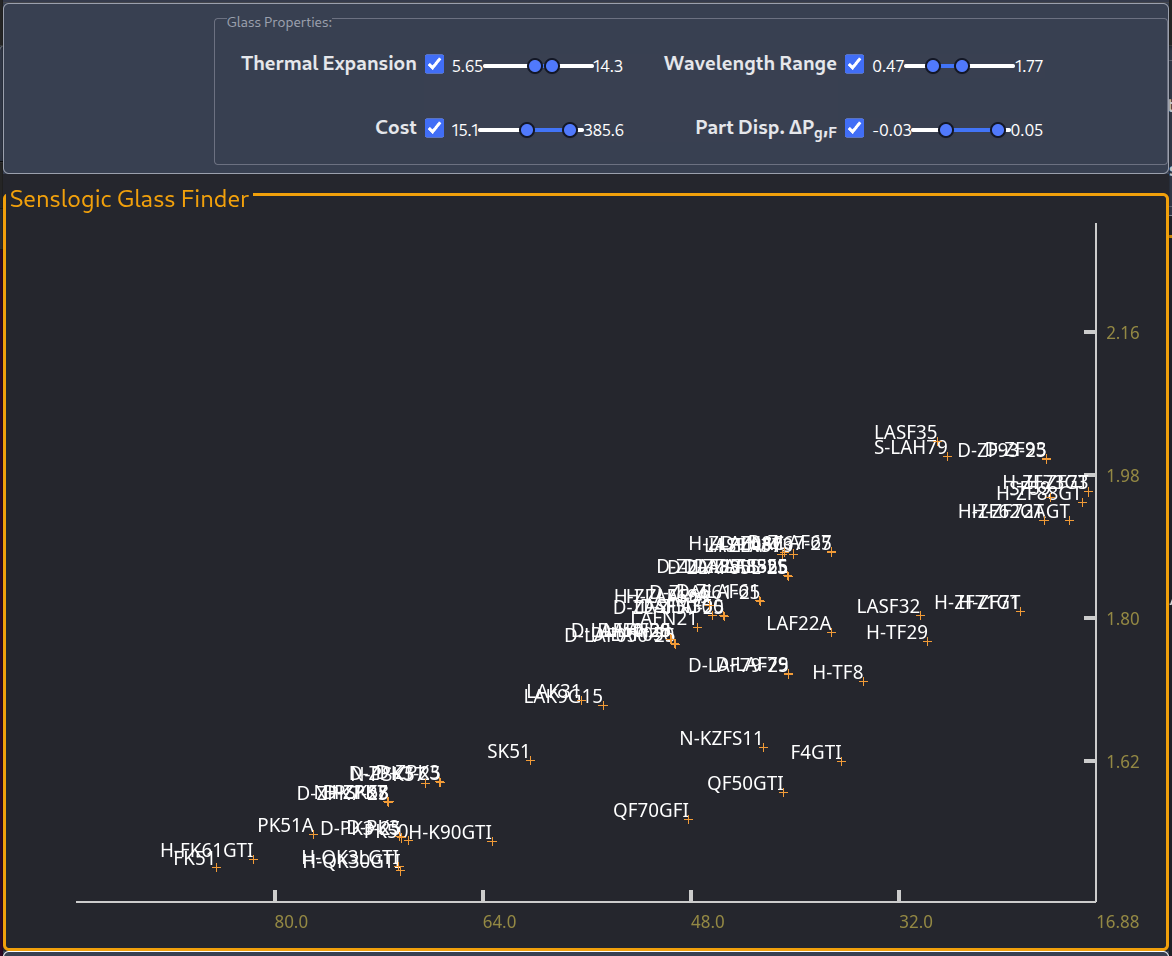

Yes, it really is in the details. Details too tiny for the eye to discern, but not too tiny for the math. A micro-lens array is not perfect. It is one of the reasons we need to calibrate it. Even though its lens centers are placed better than 250nm from their prescribed positions, the math can “see” the small deviations. They leave a statistical trace that can be detected, and detected with very good margins. To put a humorous spin on it, it’s like the prince looking for Cinderella, sifting through candidates until the crystal heel fits perfectly. To be exact, there are 7×7 candidates in our story, and the prince won’t settle for one of the stepsisters. Technically, the 7×7 candidates give the sensor roughly a 12 degree range where the prince expects to find the source, I mean Cinderella.

Why the focus on simplicity?

A very good question—I thought you’d never ask. From my experience, the traditional tools often remain unused, collecting dust on a shelf. Too often, we assemble our lab setups, or even products, with inadequate equipment, resulting in subpar outcomes. With WaveMe in general and its SH module, I’m hoping to change that—or at least take a meaningful step in the right direction. This effort also reflects our unwavering commitment to achieving expected, or even exceptional, results. If you choose to partner with Senslogic, you should expect nothing less.

Leave a Reply