How should we approach the development and integration of a new complex, high-performance optical system? First, let us clarify what an optical system is. If you look around the Internet, you will find many companies offering optical system development services, but all we get to see is an objective, albeit one with many elements in almost as many groups. In the context of this tech talk, this is not an optical system. A microscope would be somewhat closer to one, or perhaps the James Webb Space Telescope, which would be a perfect example of a high-performance optical system. Such a system presents many challenges in addtion to those that can be addressed with CODE V or Zemax/OpticStudio. It’s a bit extreme, but it’s a perfect example of what this tech talk is about.

A common approach

So, back to the topic. In my experience, most people tackling a new system would start by looking at some basic first order designs and scaling laws. Then probably some error budgets that give an indication of whether the system can be built and how difficult it might be. Probably some more detailed simulations and ray tracing would follow to quantitatively evaluate some non-obvious issues.

But the thing is, and it’s probably colored by my experience in industry, the number of critical issues in the specification is dwarfed by the number of critical specifications in the subsystems. Perhaps it is even a trivial observation that the number of critical items in the subsystem specifications by far exceeds the number of critical items in what we might call the customer specification. This is important. But why?

Let us go back to the JWST. How about we take an approach that I think is far too common. We order the parts, assemble them, book a rocket in this case, send the JWST to the second Lagrange point and see how it works. If it does not work, we take it back to the lab and fix it. No, of course that will not work. The designers of the JWST optical system did not have to spend much time explaining that they had to get it right in the first place.

The optical system designer, working on something complex yet down-to-earth, will have that discussion. There is a tendency and temptation to put things together after an initial engineering effort. “First light” and then, where do we stand in terms of customer requirements, and then, tweak. But tweak what? Here I want to go back to the assertion that the number of critical items in the subsystem specifications far exceeds the number of critical items in the customer specification. If this is where we are and we need to look for the answer to why our system does not meet the requirements, then of course, it is not as bad as bringing back the JWST from L2, but it is bad. In my opinion, this is a failure.

So how can we avoid this trap? I hope many would suggest building it from the ground up and in each step verify that the predictions of the models are met up to that point. If this is the JWST we are building, then (I suspect) almost everyone working on it is probably very well trained, highly skilled, and has all the tools needed for the task. Most (earthbound) projects do not have that good fortune.

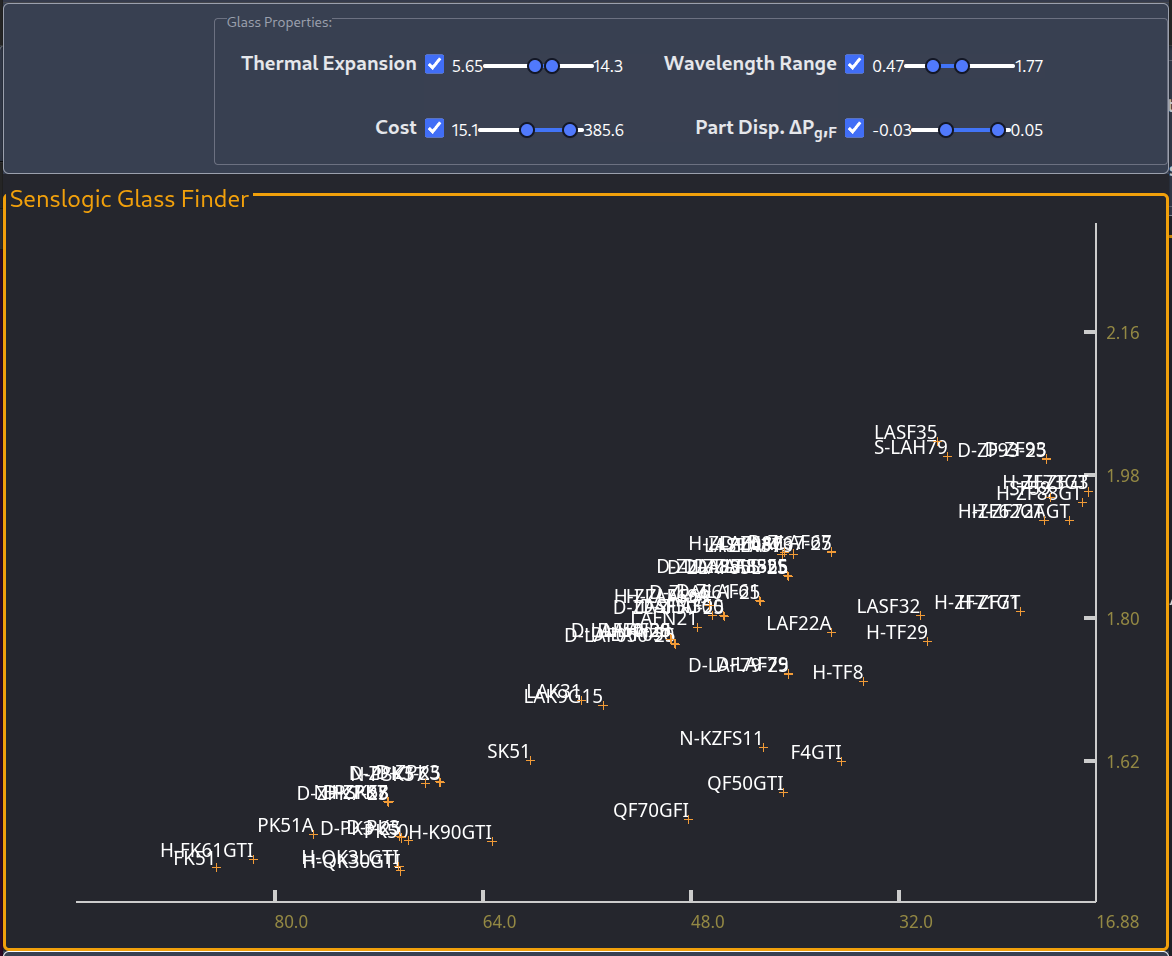

The tools are there, but too often they are not used. Perhaps they are not sufficiently adapted to the day-to-day tasks of the optical engineer. Most companies do not have billion-dollar budgets and brand recognition to attract the best talent in the industry, but they still need to supply markets with high-performance optical systems. It is in this niche that Senslogic will hopefully contribute. Watch this space for future announcements.

Leave a Reply