Introduction – Redefining CAD

When most people hear “CAD,” they think of 3D mechanical design software, like SolidWorks, AutoCAD or CATIA. It’s a natural association: the tools are visual, tactile, and tangible. But should CAD, in its literal sense—using computers to aid in design—be limited to just this mechanical space? It’s a leading question, I know. Yet much of the optics industry still seems stuck in that mindset.

Current Tools – Mappings, not Design

I can imagine many of those who read this think, “but we have Zemax, or Code-V“, or “what about LightTools, Oslo, or Fred?”. Fair point. We do have those tools, and we have them for good reason — they work. But let me counter that with a question: How many parameters (or numbers) come out compared to how many go in?

What does that have to do with anything? Well, if I have to provide 10 numbers and get 10 numbers out, are these tools really giving us answers — or just mapping inputs to outputs without adding real insight? How do you know the results are meaningful unless you already know the inputs are correct? It might sound blunt, but the old computing rule still applies: garbage in, garbage out. Input matters.

Vision – Designing Without Assumptions

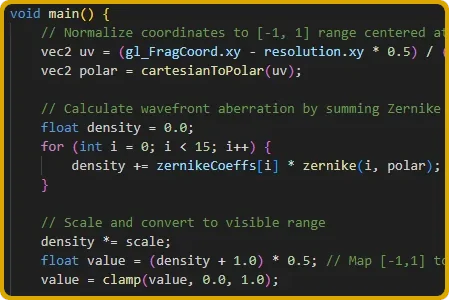

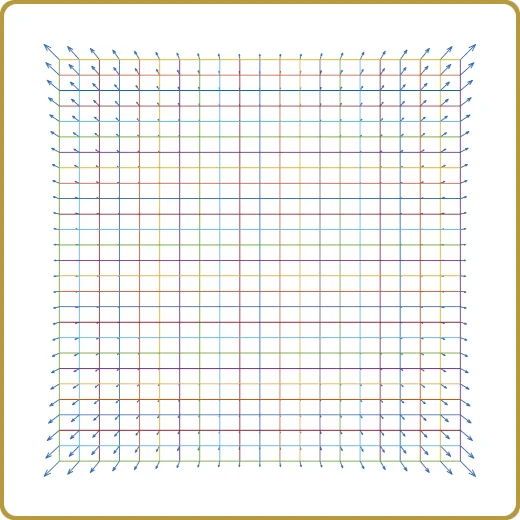

Can we design products without making assumptions? I believe we can, and the computer is the tool for it. No big surprise there. The way to get there is to connect the free parameters of our systems, such as all the parameters we need as input for ray tracing tools to do their magic, to performance parameters.

As a generic example, consider a system that takes in laser light, transforms it, and produces some desired effect. In the computer, we can model this entire process—right up to assigning a value to the outcome that the customer can recognize and connect directly to commercial performance

In the litho industry, he would recognize minimum feature size, CD uniformity or registration. He would not be able to relate to a number for spherical aberration or coma, no matter how good your optics are. That does not tell him what he needs to know, and neither do most product owners.

Application – Real Performance Metrics Matter

However, when we tie our design parameters to performance parameters through models, not only will we connect what our customers want with what we need to do, we will also learn how the system we’re designing is internally connected and this can be a great insight not only to how the requirements are connected with our design targets for individual modules, but also where our priorities lie.

The Application Engineer

While on the topic of application, and this is a bit of a segue, application engineers will really benefit from proper system software support. It’s practically an impossible task to be the technical frontend to the customer as well as staying on top of how things actually work.

Builing system simulation tools is expensive, so why not reap the benefits on all fronts, and include application engineers.

With custom software, we can also decide how to distribute this software, and the browser has become a very interesting frontend for doing this. There’s almost no difference building graphial user interfaces for the desktop and for the browser, where the later allows us to completly sidestep distribution questions, platforms and installers. The browser (with so many of them being based on chromium) offers a very unified and stable platform, well worth exploring with tools like Leptos or Dioxus (Yew, and many others). It’s an interesting infrastructure that is being developed that I believe has a place in this space.

The Theory in Practice

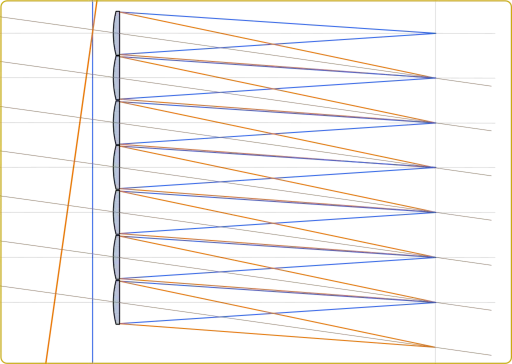

While all of this sounds generic and theoretical, this design in the computer approach was used to design the LDI-5s direct write system from the ground up. At the time, we had never designed for dry-film resist, in a first mixed-imaging (incoherent-partially coherent), anamorphic, mixed pixel-size, UV system. What we knew at the time was 2D SLM, clean mask writer system, high-contrast resist, and a 2 giga-pixel per second modulator with 80 mm/s scanning speed with a nearly ideal light source, the excimer laser. Now, we needed to design with a 1D modulator, scanning at 2000 mm/s with four rotating telescopes to achieve 60 seconds write times over 500mm x 500mm substrates, and had we tried to guess any of the parameters affecting the optical system, the risk of having to do it more than once was quite real.

However, this design was all but exhausted in the computer. Writing characteristics, SLM micro-mirror dynamics, optical subsystem requirements, NA (different in X and Y), pixel size (different in X and Y), was optimized in the computer. Every aspect of the machine was pushed to its limits. Even the SLM, used at a pixel rate of 2MHz, was used above its mirror resonance frequency. The link claims 1MHz pixel rate. Interestingly, with “future perspective: up to 1.6 MHz”. To this yours truly will add, 1.6 was the factor between pixel rate and resonance frequency. The modulator could be used above its resonance frequency thanks to critical micro-mirror damping and ratio of optical resolution and pixel size of about 0.2 — rather small even for a mask writer, but dry film resist need to be exposed much above the iso-focal dose so the optical resolution of the system is substantially higher than the minimum feature size. A tough choice to make for a system which screams “give me writing capacity”, but one you can make if you can back it up by numbers and track record.

We even provided metrology tools for system integration.

This is Senslogic

This experience, and how well it worked out, will be found in the range of services provided by Senslogic today. Readers will find bits and pieces of this story in various tech-talks on this site, but I think this is the first post framed in this Computer-Aided Design perspective.In my opinion, the lab is not the place to learn – the computer is. The lab is the place to verify your models. The lab isn’t where you learn — it’s where you verify. It’s where you build confidence in your process. Design once. Build with confidence — any time, every time.

Real-life example

I have to mention something that happened yesterday. I have been wrting a lot of modeling software for a customer, related to first principles modeling, image analysis and handling software.

The meeting started with something like, “Jarek, I think you are going to like this”. “Can you see which of those images is simulated and which one is captured with the camera”. And literally, each image is a sum of 100 images brought together from different positions and different object configurations. It’s a fairly complex exposure system, both in the lab, but obviously also the modeling.

It took me a while and only because I knew there was still a difference between the model and the lab setup, so I knew what to look for, but also thanks to the quality of both results that would reveal tiny oscillations.

But the point is, we did a lot of research with the modeling tools and after all that effort, it was great to see those results reproduced in the lab. It was like being part of the A-team: “I love when a plan comes together.”

Leave a Reply